Metal-organic frameworks cut energy consumption of petrochemicals

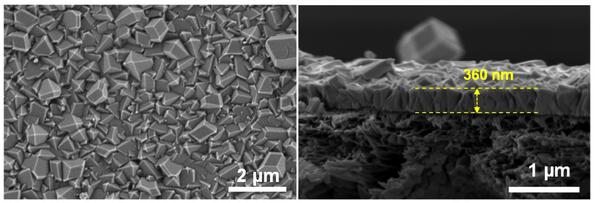

Electrophoretic nuclei assembly for an energy-efficient separation membrane (credit: K.V. Agrawal/EPFL)

Chemical Engineers at EPFL have developed a new method for making metal-organic framework membranes that can be used to considerably improve energy-expensive processes such as propylene-propane separation, which accounts for 40% of energy used in the global petrochemical industry.

In the chemical and the petrochemical industries, separating molecules in an energy-efficient way is one of the most important challenges. Overall, the separation processes account for around 40% of the energy consumed in the petrochemical industry, and reducing this can help addressing anthropogenic carbon emissions.

One of the most important products in the petrochemical industry is propylene, which is widely used in fibers, foams, plastics etc. Purifying propylene almost always requires separating it from propane. Currently this is done by cryogenic distillation, where the two gases are liquefied by being cooled to sub-zero temperatures. This gives the propylene-propane separation process a very large energy footprint.

A solution is to use “metal-organic frameworks” (MOF’s). These are porous, crystalline polymers made of metal nodes that are linked together by organic ligands. The pores in their molecular structure allow MOFs to capture molecules so efficiently that they are now prime candidates in carbon-capture research.

In terms of separating molecules, MOF-based membranes are among the highest performers, and can carry out the propylene-propane separation at ambient temperature. One MOF called ZIF-8 (zeolitic imidazolium frameworks-8), allows propylene to diffuse through its pores 125 times more efficiently than propane at 30oC, offering high selectivity without the need for sub-zero temperatures.

“The main challenge with this approach is to synthesize high-quality, ultrathin, MOF films on commercial porous substrates without complicated substrate modifications,” says Professor Kumar Varoon Agrawal at EPFL. “Such high-quality films have fewer defects and are necessary for obtaining the highest possible separation selectivity.” His lab at EPFL Sion has now developed a straightforward MOF crystallization approach called “electrophoretic nuclei assembly for crystallization of highly-intergrown thin-films” (ENACT).

The ENACT method allows simple regulation of the heterogeneous nucleation on unmodified (as-obtained) porous and nonporous substrates. This in turn facilitates the synthesis of ultrathin, highly intergrown polycrystalline MOF films.

Ultrathin MOF membrane on commercial polymer support (credit: K.V. Agrawal/EPFL)

The lab used the ENACT method to synthesize 500-nm-thick MOF membranes. When they tested them, the membranes yielded one of the best separation performances in propylene/propane separation recorded to date. The ultrathin film yielded large propylene permeance (flux normalized with pressure difference), which will help reduce the membrane area needed for industrial applications.

The group concludes that the versatile, straightforward ENACT method can be extended to a wide-range of nanoporous crystals.

European Union (Horizon 2020)

G. He, M. Dakhchoune, J. Zhao, S. Huang, K. V. Agrawal. Electrophoretic Nuclei Assembly for Crystallization of High Performance Membranes on Unmodified Supports. Advanced Functional Materials, 12 March 2018. DOI: 10.1002/adfm.201707427